DECCO® Solenoid Troubleshooting

The failure of an original equipment solenoid can often be traced back to the condition of the product installation. These conditions are simple to spot, and with a little practice, you can do your own Decco solenoid troubleshooting!

Overheated Solenoid

Standard Decco coils are rated class 105°C, which means that they can safely reach and sustain temperatures up to 105°C or (221°F) -temperatures hotter than boiling water! Therefore, a solenoid too hot to touch may not be overheated.

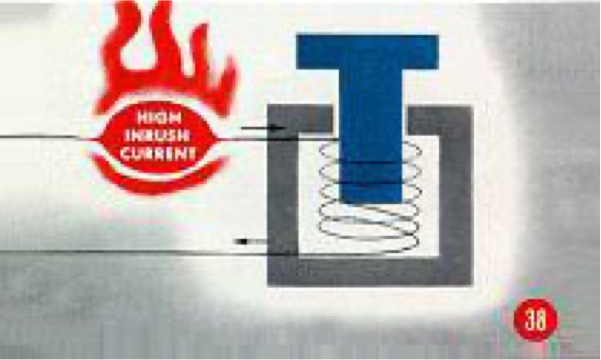

Energized Solenoid

Remember, when a solenoid is energized, the coil receives a pulse of high inrush current which decreases as the plunger closes.

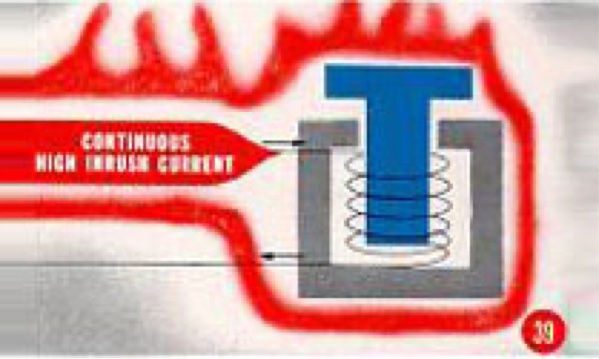

Coils Burnout

If, for any reason, the plunger does not close, the high inrush pulse continues, and the coil overheats and burns out. This type of coil burnout is the most common cause off solenoid failure. It's easy to spot.

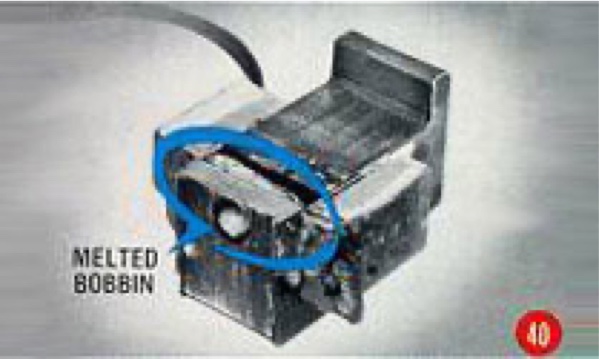

Melted Bobbin

When a coil burns out, the bobbin melts and nylon runs into the space under the plunger. If you find melted bobbin material, check to see if the plunger was mechanically blocked open. On a double solenoid valve, see if both solenoids were energized at the same time.

Supply Line Voltage

Another thing to check is the ambient temperature. If the ambient is too high, the coil will lose its ability to dissipate heat. Resistance increases, current flow and force are reduced, and the solenoid will not close. Result- coil burnout.

Ambient Temperature

Another thing to check is the ambient temperature. If the ambient is too high, the coil will lose its ability to dissipate heat. Resistance increases, current flow and force are reduced, and the solenoid will not close. Result- coil burnout.

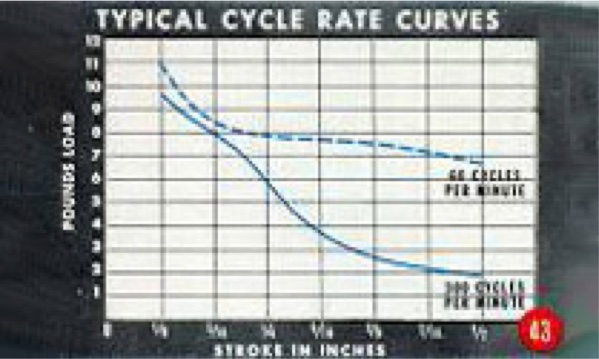

Cycling Rate

And finally- check the cycling rate. If cycled too fast, heat will build up faster than it can be dissipated. The solenoid soon becomes too weak to close, receives a continuous inrush current, and burns out.

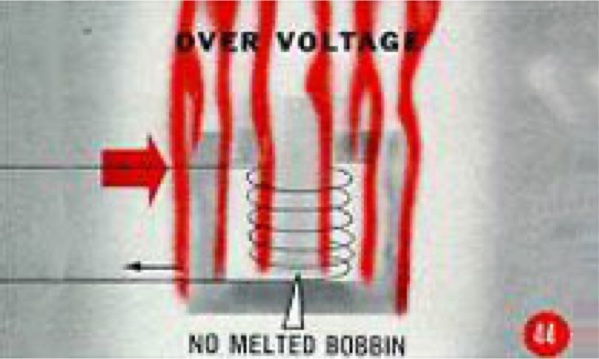

Overvoltage

In rare cases, a solenoid coil will burn out due to OVERVOLTAGE. The plunger WILL close, because the solenoid has extra force. (You'll find no melted bobbin.) The high voltage causes excessive holding current which will overheat the coil and burn it out.

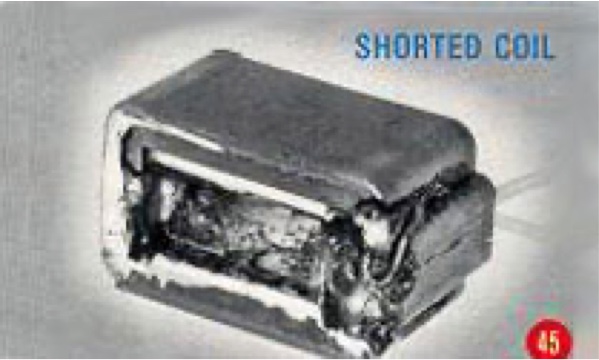

Shorting

Another possible cause of coil burnout is SHORTING. Water base coolants often carry fine metallic particles from a grinder or other machine tool. Splashing or soaking can cause shorts between the coil's lead wire junctions.

Excessive Force

This "C" stack and plunger were subjected to excessive force for a long period of time. Note the worn copper shading coils and the deep grooves in the "C" stack and plunger laminations. This causes the air gap at the base of the plunger to disappear.

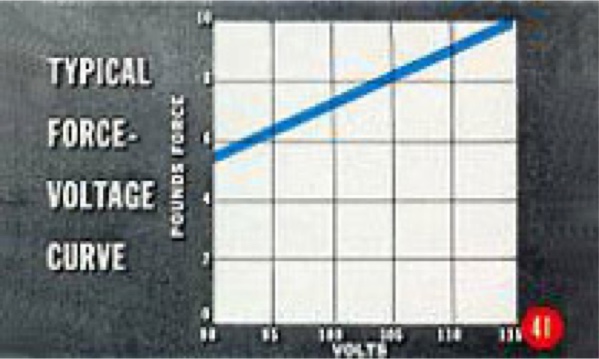

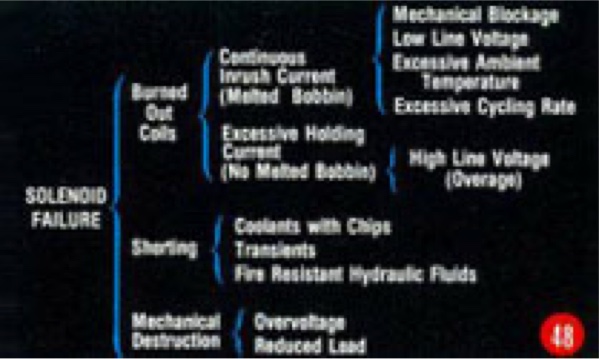

The Chart

When you put everything together, you get a chart that looks like this.

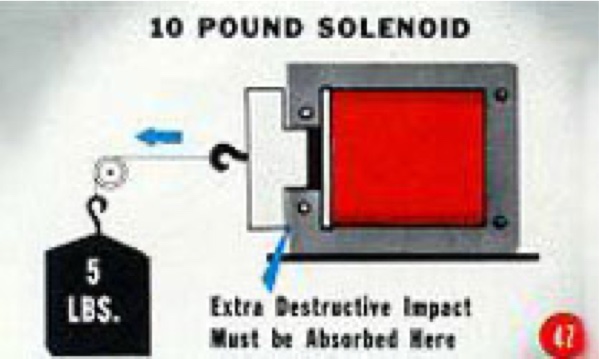

Hammered To Pieces

A solenoid can literally hammer itself to pieces. Excessive force can be caused either by overvoltage or by a reduced load on the solenoid, and must be absorbed when the plunger hits the "C" stack or field. Be sure the solenoid's force closely matches the load.

Have a Question?

If you have any questions regarding our custom solutions, new product development involvement, or would like to learn more about Decco get in contact with us! Fill out the form below and we'll get back with you shortly.